Review: Chris King R45 Ceramic Wheelset

Chris King is like Frank's Red Hot…. I put that 'ish on everything! Here's proof. If you read the component chapter of my Perfect Project, you'll know that I appreciate Chris King for their quality, reliability, and their serviceability. That appreciation has a bit of its own history. As a young BMXer, I lusted for the opportunity to kit out with their headsets and bottom brackets. Now that I'm all grown up, I'm fortunate enough to deck out my road bikes in Chris King components and because of it, they've become very familiar to me.

When a member of the Chris King organization reached out to me in the fall of 2017, they asked if I would be interested in reviewing one of their factory built wheel sets. A definite rhetorical question - of course I would! But I already had a couple wheels with Chris King hubs, so what would be different? Well, two things. First, these new wheels would be built in house by their staff, which would offer an opportunity to compare them to the quality of stock machine laced wheels or to those that come from local custom builders. Second, since this review period would take place over the winter, these would be sporting ceramic bearings. Oooooh!

I'm usually pretty particular about my setups, but I put my OCD tendencies aside and let it all be chosen by the Chris King team. They designed and chose a wheel set that would be ideal for riding through the Canadian winter and bumper seasons. This meant R45 hubs with ceramic bearings, higher spoke count, and aluminum rims - Ok I didn't give up full control. I did insist on the new matte punch pink colour. The following is my detailed review and tear down.

Who is Chris King?

Before I dive into the details on the wheelset, let's establish a baseline. Who is/are Chris King and why does it matter?

Chris King, yes he is a real person (the personal and business references may get confusing) who started building bike parts over 40 years ago, in 1976. The idea to build his own parts began while working in a local bike shop and observing what could be improved on a bike. His experience and his influencers pointed him to the headset. Why? Because the quality of headsets available at the time were subpar. But simply milling a higher quality headset shell wouldn't be enough for Chris. At the heart of the headset are the bearings. And so to make a truly better product, Chris needed to make better bearings. Something that still remains a source of pride today.

Resources: SHOP VISIT: Chris King Precision Components (Bike Component Heaven!)

As you can imagine, a lot has changed since 1976. They've gone from making headsets to a full catalog of parts that span multiple disciplines of cycling. There was even a period of time when they had their own brand of bikes, Cielo.

Everything they do seems to be calculated and because of that , they haven't built success by chasing fads and trends. In fact, one of the criticisms of Chris King is that they are too conservative when it comes to innovation. As an example, they just announced their first internal headset. And it was only recently that they made the move to ceramic bearings.

Outside of product development, one of the more recent business changes at Chris King is the availability of fully wheel builds originating at their factory. That's where my wheel set came from.

Design & Construction

My wheelset was hand built at their facility in Portland, Oregon, and arrived well packed in a Chris King branded box (designed in collaboration with FedEx.) Inside said box, I found my new wheels, a pamphlet and a set of brake pads. All of which I opened up like a kid on Christmas morning. At the core of the wheelset are the legendary Chris King R45 hubs. Why are they so special? The product name gives you hints.

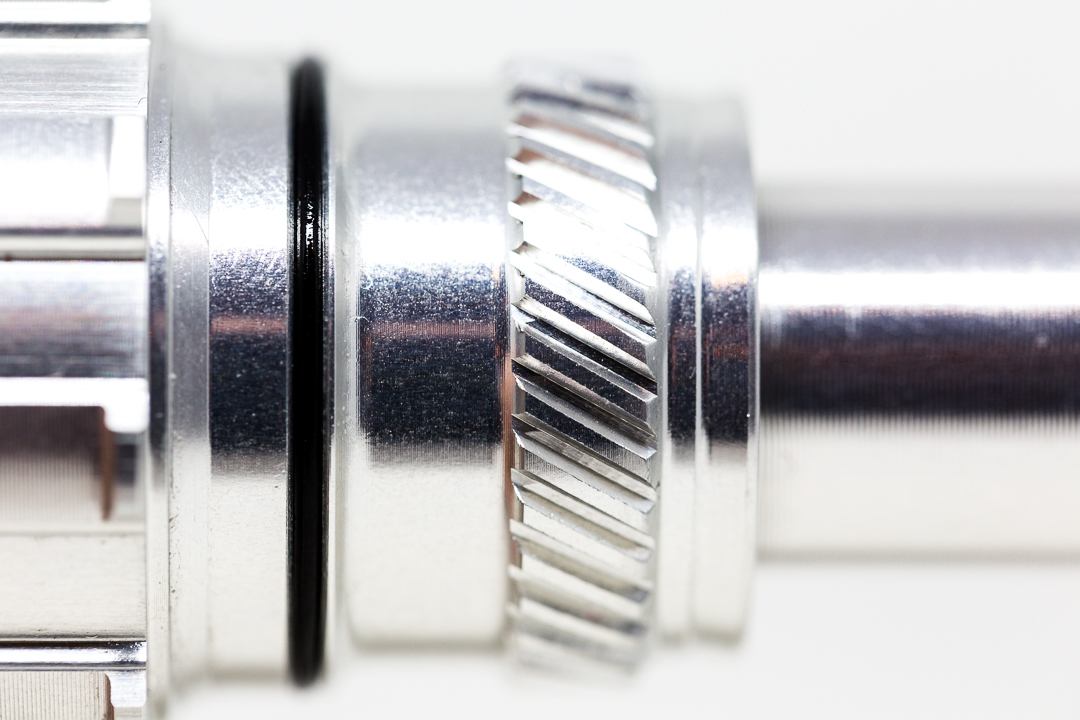

The R stands for road and means the specs are for current (although do offer some backwards compatibility) road bikes. And the 45 in the name refers to the 45 points of engagement in the ring drive. The ring drive is what is responsible for the near immediate engagement and that legendary angry bees sound that Chris King hubs are known for. But how does that work?

Resources: How Things Work - The Freehub Body

For it to make sense, I have to start by explaining the two main drive types available in hubs today. There are pawls and there are star ratchets, also know as face gears - and not all are created equal. The common ratchet and pawl systems use… pawls to engage the hub and the freehub. When pedalling, the freehub is rotating in a direction towards the teeth on the hub ratchet. Tiny leaf springs or coils push the pawls outward where they lock in and thus drive the rear wheel forward. But when at rest, the freehub remains static and the pawls draw slightly inward. When this happens the teeth on the hub side ratchet draw across the backs of the pawls, allowing you to coast. The downside is that the large spacings between the pawls means that the hub will have to coast for a period before the teeth of the ratchet side lock onto a pawl. Although the design works, this means energy and effort lost in slower engagement. That's why higher end pawl drive type hubs can have 6 pawls when 3 is more common.

Now this is where face gear type hubs come in. Like pawl type hubs, a star ratchet still uses a toothed ring (ratchet) on the hub drive shell. But the key difference is there is also a ratchet on the freehub. In the case of the Chris King R45 hub, each of these rings have 45 teeth. The way this works is that when you apply force at the pedals, the ratchet on the freehub is forced inboard to lock up with the ratchet on the hub. The opposing teeth grab onto each other and drive the hub shell forward. When you stop pedalling, the freehub stops moving and the ratchet slightly retracts, allowing the hub shell teeth to slide over and the wheel to spin freely. The sound of the 90 teeth slightly brushing each other is where the angry bee buzz comes from. While the ring drive system may employ some friction or resistance as the teeth brush each other, it's nominal at best. And to be honest, if you're worried about friction resistance while not pedalling, we should have a conversation about why you should always be pedalling.

Resources: GCN Tech interview with Chris King Ask Chris King Anything | Ceramic Bearings, Freehub Noise & Bottom Bracket Standards

What else makes the Chris King R45 hubs different? The bearings! While outsourced bearings are widely available and in various grades of high quality, the bearings in Chris King components are something they are very proud of. They are made in house under strict quality control. They do this to create the best bearings they can and ones that they say get better over time. Now let's break down the bearings.

A cartridge type bearing (that's what's in your bike) is made up of a few key parts. There are inner and outer races, ball bearings, a carrier, grease, and seals. When they say that Chris King bearings are made in house, they are referring to the races, not the ball bearings - just to be clear. The inner and outer races are circular rings of stainless steel and their key purpose is to house the ball bearings. The outer race is sized to fit tightly into something else - whether that be a bottom bracket shell, a head tube, or a hub shell. The outer race remains static and doesn't move. The inner race, which is smaller, is sized to fit firmly around something - this could be your fork, cranks shaft, or an axel - something that moves. Chris King machines these races in house to their own extreme tolerances based on specific criteria needed for cycling.

Between those two races are the ball bearings. These incredibly sophisticated ball bearings rotate as the inner race moves and outer race remains in place. The ball bearings (more on those in a moment) are kept evenly spaced apart by the carrier. In the case of Chris King components, these carriers are made of polymer (plastic).

There are also the grease and seals. While having no grease would technically offer the lowest rolling resistance, this would only be true as long as the bearing was completely clean. So a low friction grease is used to help keep all the parts moving smoothly. And a plastic seal is used on the exterior of the bearings to keep dirt and moisture out.

I've been riding steel bearing R45 hubs for a very, very long time. But remember that for the review, the wheel set came with ceramic bearings. Unless you've been living under a rock, you'll have noticed that everything ceramic is super popular in road cycling right now. Pretty much anything that moves, spins, or rotates can now be upgraded to a ceramic bearing option. But what's the point?

There are claims out there that ceramic bearings improve performance by offering more watts savings via lower resistance. If you ask me, that's about as true as it is untrue. The resistance improvements of ceramic bearings are so small and marginal that it doesn't make for any impactful benefit to the common cyclist - unless you count happiness, smiles, and the placebo effect. Sure if you are a pro cyclist who’s looking to squeak out every last ounce of wattage, go for it. But I'd argue that the real world quantifiable cycling benefit of ceramic bearings is actually in general performance over time and compounded by poor conditions.

Now that I've made a contentious point, I'm going to explain myself. Ceramic ball bearings are made from silicone nitride (Si2N4). When compared to steel ball bearings, the ceramic itself is able to be polished and shaped down to far greater degrees of both roundness and smoothness. To quantify these traits of a ball, they are classified in grades as single and double digits. Those grades refer to the accuracy down to 1,000,000 of an inch. So the lower the number, the more accurately round the ball is. A high quality steel ball is usually around a 25 grade, but a ceramic ball can be made with much greater precision and their grades reach well into the single digits. Why does that matter?

Resources: Ceramicspeed (Ceramic) bearings versus Steel Bearings... An engineering explanation

Ceramic fans claim the lower rolling resistance means more watts saved and sent through to the road. I agree that effective lower rolling resistance is true… in non-cycling applications. You see, ceramic ball bearings were created for high RPM (rotations per minute) use cases - those greater than 10,000 RPM. Such as in motorized machines, automobiles, etc. At those speeds, the greater minute perfections of the ceramic ball and its higher resistance to heat distortion add up to higher efficiencies. But the RPMs of cycling just doesn't get anywhere near there. And truth be told, the greatest source of energy loss in a cartridge bearing is actually the seal anyways… and then the grease. You stand to gain more watt savings by servicing your grease or using no grease at all, than you do by changing the type of ball bearing material. I'm not saying you don't save anything, it's just not anything really impactful enough to say this the key benefit or ceramic bearings.

So if it's not really that revolutionary, why would Chris King use ceramic ball bearings at all? Ceramic is also much harder than steel, up to 30% harder in fact. This means that by nature, ceramic ball bearings will be more resistant to abrasion from rust or by foreign particulates (dirt) that are introduced to the grease within the bearing. Even though cartridge bearings are sealed, they still get dirt inside. Water can also get in there and wash out some of the grease making even more room for dirt. Even after you flush the grease (which is user serviceable on a CK hub - Chris King Hub Basic Service Video), the pitted surfaces may keep grinding away. With that in mind, the idea is that ceramic balls being much harder, will stay smoother for longer. Meaning that if you ride in poor conditions like winter, dirt, mud, or are generally not very good at maintenance, ceramic bearings will offer greater longevity and smoother bearings.

Sidenote: The greater hardness of ceramic also means that that hardness can end up working against you in cheaper bearings. The ceramic ball itself being much harder than the steel race, a sudden impact or load on the bearing may cause the race to hit the ceramic ball, causing tiny indents in the surface of the race which will then compromise the smoothness of the surface and over time, create a rough rolling bearing. So don’t buy cheap bearings!

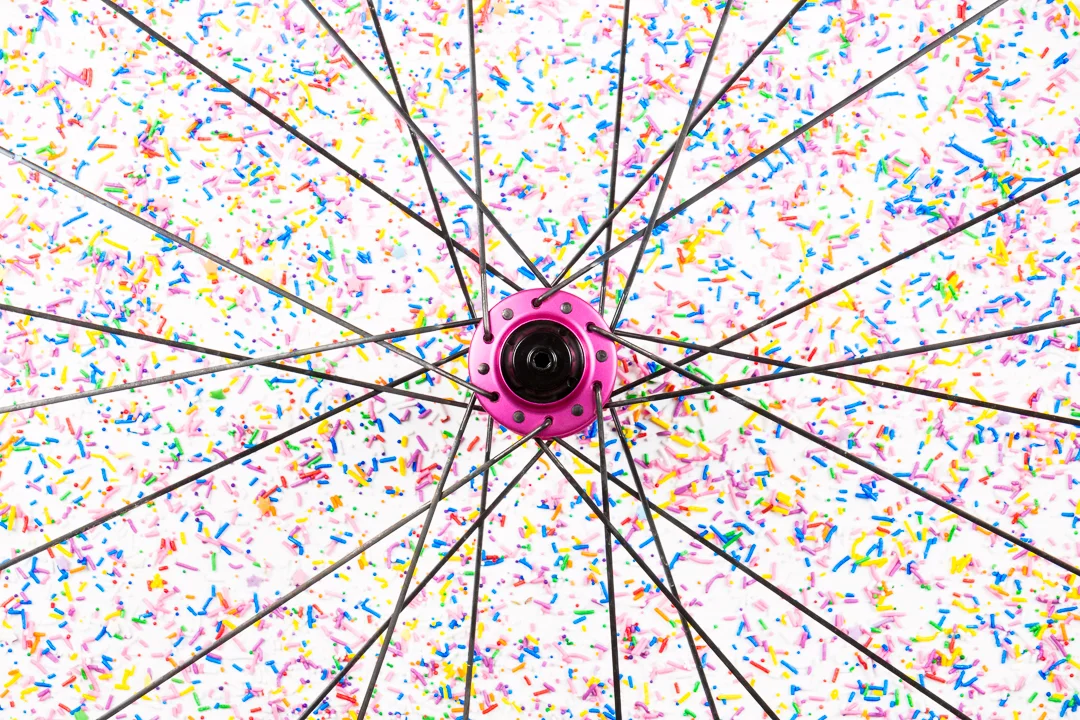

With that all now out of the way, let's turn attention to the build details of the wheels I rode and am reviewing. Starting at the R45 hubs, my wheelset came in the new matte punch pink color. This is a new color and finish that Chris King introduced late in 2017. The matte finish is hand blasted to a high textured surface. The new punch pink color is much bolder that the older, now gone, limited edition pink (my favorite) that ended in 2016. I'd describe the current shade as more raspberry than the previous bubble gum. What's also new in the R45 hubs are the black anodized freehub body, preload caps, and axles. For a definite stealthier look.

For the review, the hubs were paired up with a set of HED Belgium+ rims. These 25mm external width aluminum clincher rims are the same as the HED Ardennes+ but available as rims only. That’s really the only difference. Since built for road cycling, the Belgium+ are obviously a 700c size and have a 24mm depth with a machined braking track. HED claims a rim only weight of 465 grams, but since mine were complete, I only know the final build weights. When you add them to the combined 324g (claimed) weighted R45 hubs, the final build with Sapim CX Ray spokes tipped my Park Tools scale at 705g for the front and 835g for the rear. That's a combined weight of 1540 grams. Not bad for a modern wide rim aluminum clincher. For that extra added pizzazz, the two nipples on either side of the valve holes were anodized in pink to match the hubs. This helps add some personality to the wheelset and to make it easier to find the valve for inflating and changing tires.

First Impressions

Getting a big Chris King logo'd box delivered to your door might be like reliving christmas morning. It's hard to hold yourself from tearing it open on the front porch. But I am civilized, so I hauled the box inside to pry open in private, away from judging neighbors.

In my day I've seen some really expensive wheels shipped in boxes that can only be sent out with a hope and a prayer. But in this big brown cardboard box I found my new wheelset packaged with love and care. These were aluminum hoops but I wouldn't have worried if they were carbon.

At first glance the matte punch pink color is much more vibrant in person. The photos on the Chris King website and all over social media just don't do it justice. Even with the matte finish, it's crazy hot. Kudos to their design team for figuring out the anodizing and for having the courage to put it out there. Black may always be the new black, but the Punch Pink is going to be popular.

Once I had the wheels out of the box and in hand, you know the first thing I did was spin up that rear hub to listen to that angry bee. It's. just. so. satisfying. Besides the audible joy, the wheelset felt super sturdy and well built. The ceramic bearings were rolling smooth, just like all brand new bearings do. But knowing they were ceramic, I just believed them to be extra smooth - whether I could truly distinguish this or not. What I could tell is that to my hands, the wheels felt like they were rolling round, dished, and true. And that's a big deal. Most stock wheels are either completely built by machine or are at least finish by a real person. This usually ends up with a wheel that needs to be checked over by a proper wheel builder and adjusted. When I posted them on my social feed, I started getting messages right away from wheel builders asking how they were and a couple even asked if they could check out the build quality first hand. Don't worry, these were bangin' right out of the box.

There is no doubt that the new HED Belgium+ rims are WIDE. They are a beefy set of rims and are definitely on the bleeding edge of current trends with their 25mm external width. When I slapped on a set of 25c Michelin Pro tires they got chubby. Measuring just a tick shy of 29mm on the rubber. The plan was to use all that extra rubber for a cushier and confident ride over rough winter road conditions. It only took a few minutes to get the rubber and tubes on and get mounted on the bike. Where the setup did slow down was in setting the brake pads. Included with the wheels was a set of Kool Stop Dura 2 brake pads which I swapped in place of my SwissStop carbon pads from the summer wheels. The Dura 2 pads are rated for all seasons and have a softer compound than stock Shimano aluminum rim pads. Despite having a more curved profile, which helps for setup and braking, the HED Belgium+ rims have a noticeably narrower brake surface. This meant it took longer to get everything lined up. Nothing too hard but something to be aware of if you're a home mech.

Now that the wheels where on and the pads were set, I gave the rear wheel a run on the stand. They spun up nice and smoothly, but I noticed that the crank was stepping forward while freewheeling. And that the wind down was markedly shorter than my own R45 hub'd wheels. It was like the Ring Drive was not fully disengaging. Why was this happening? Don't freak out. That’s a visual sign of the break in period. Chris King recommends a break in period of a few hundred miles. That’s so the seals will form to their final shape and the bearings will burnish a track on the races. When this is complete the bearings will be have far less drag.

Tip: Never race on Chris King wheels without breaking them in first.

On The Road

Considering winter riding is never the most comfortable, the new Chris King wheelset were super cush. They rolled smooth like butter with the 25c tires spreading out and laying down a wide contact patch. Everything takes time to break in but on the first ride I noticed that this R45 rear hub was quieter than expected. The difference in volume of the ring drive is thanks in part to the aluminum rim. Alloy rims do not resonate the same way a deep carbon rim does. By spring the stepping forward of the crank while on the stand is no longer present.

While the HED Belgium+ rims tick all the current trend boxes with their wide internal and external width, matte black finish and a machined brake surface (which provides adequate braking as expected), a toroidal shape, all with a relatively low weight, the 24mm depth seems to catch more side wind than expected. It may just be more noticeable in the winter when the winds are stronger around here, but at times I felt like yaw winds were blowing me around as much as when riding deeper carbon rims.

The build for this wheelset spec'd out with a 24x28 spoke count. While most people are cutting spokes to save weight I've always believed that saving 3 grams per spoke is not worth the loss in stiffness and reliability. Especially after exploding a hub flange on a lower spoke count wheel set. That’s why even though a 24x28 was chosen to stand up to harsher winter road conditions (pot holes!), it's actually my preferred spoke count for everything. In riding these wheels over the winter I felt confident that the high spoke count contributed to a stiff and responsive wheel that had no fear of Toronto's deplorable roads. This is good because I was purposefully looking for trouble.

Despite knowing that the ceramic bearings should fair better in dismal conditions, I swear I wasn't setting out to ride in the cold winter rain. But it seemed like mother nature had different plans. Almost every time I went out, it rained. Ugh. And I didn't do a thing about it. I left the wheels as is, covered in muck, grime, and road spray. The only washing out they ever got was when I rode them through slush puddles. Out near my house is a quiet road that ventures out along the lake through a nature preserve. It's very calm and secluded in the winter, but it's not maintained very well. And thus, a prime hunting ground for icy and slushy sections. On a few occasions I headed out there and road straight into them. One puddle went right up to the hubs. Didn't seem to make much of a difference though. Everything kept rolling true and smooth.

At the end of the season I gave them a proper wash down and was fully expecting the wheels to look like they'd been trashed - I've had rims that wore down in one wet ride. Yet they look no worse for wear. After dousing them in a season's worth of road salt and grit, you'd think the hubs would feel like were spinning in wet sand. Nope. Either the sealed bearings work that well or the ceramic truly is more resilient.

Even though the intention was only to do a winter and foul weather season review, it takes a month for the rain to wash the sand and salt off the roads, and the city takes forever to attend to all the potholes. That meant I got to keep the wheels going for a little bit longer before swapping over to the summer carbon wheels. In the extra month or so, the hubs continued to roll smooth, and like all my other R45 hubs, kept breaking in. It's nice to see a product that was made to last, not to get you to the next purchase cycle.

Critiques

When I think about what I would change about the Chris King R45 hub and or the ceramic version it wouldn't be much at all. I honestly didn't notice a revolutionary difference in the day to day riding. They just work. But all that performance, reliability, and serviceability comes at two costs. First is in actual dollars and cents. There is a premium paid for the R45 hubset when you compare them to other 11sp aftermarket hubs with star ratchet type engagements. And then even more so when you upgrade to the ceramic bearing option. The base steel bearing rear hubs will run you ~$764USD (based on list price at time of writing) and the ceramic upgrade is an additional $200. That puts your hubs alone at just shy of a grand. Pretty pricey.

The second cost paid in the choice to run Chris King R45 hubs is in weight. In a weight weenie world, consciously making a choice for heavier components is like a cardinal sin. The combined weight of the hubset is about ~324gr. Compare this with some offerings on the lighter side at around 200 to 250 grams. That's a difference in the neighbourhood of 124 grams or 1/4 lb. There aren't many places to shave that much weight off your bike all at once. It's a decision to be pondered when spec'ing out your next wheels. But when you compare the differences in performance and longevity, it will come down to what you prioritize. And if it makes you feel any better, if you're going to add weight anywhere in your wheels it's best at the hub.

If you're thinking about buying a complete wheel set, the HED Belgium+ rims are also sort of confusing. Aside from the frustratingly narrow brake track, the max PSI spec'd for the rim is only 90 PSI. This conflicts with the minimum recommended pressure of higher end tires will exceed that limit. Truth be told, I ran mine at 95 front and 100 rear all season without issue. Just sayin.

Bottom Line

Spoiler alert, you're not going to find much new in here. If you can't tell, I've had and am still having a great time riding this wheelset. My long term experience with Chris King R45 hubs (remember I have them on 3 wheelsets) and all Chris King parts for that matter, has been really positive. So it's not hard to believe that any of those feelings would suddenly change now. The latest generation of R45 hubs keep with tradition and just work. All. The. Time. The new color really pops and the newly anodized axel and preload caps addresses an irk I've always had.

I've found Chris King to be a top choice of custom wheel builders everywhere. But what do you do when you don't have one in your area? Well now you can log on with Chris King and get a set hand-built up by their techs. Yes this bit of competition to local builders may be a bit of touchy subject but I'm really stoked to see them offering this service because I think it affords more people the means and opportunity to learn why custom wheels are so much better. If you're timid about going custom or don't know who to turn to, you now have a really solid and easy option.

If you're trying to find out what all the hype and benefit is of ceramic bearings, or trying to decide if you should take the upgrade, my advice is to really consider and analyze your needs. Ceramic ball bearings offer small gains in hardness and precision but they won't provide revolutionary performance benefits. And definitely not something you're going to feel out on the road. Ceramic bearings are best suited for foul weather, harsh conditions, dirty roads (like gravel?) or maybe even for those cyclists who are delinquent in their maintenance. The cost of the upgrade from steel to ceramic bearings isn't cheap but the good news is that if you're already running a set of R45 hubs with steel bearings, they do offer an upgrade package which can help keep costs down by not having to buy all new hubs.

At the end of the day I loved the wheelset that Chris King picked for me. They were a great choice. In fact, I loved them so much that when the board of the Northern Pass asked what wheels we should spec out the grand prize No. 22 bike with, I excitedly suggested (maybe demanded) these exact wheels. That's right, one lucky rider in the 2018 Northern Pass ride went home with a custom bike rolling on Chris King built wheels with R45 hubs and HED Belgium+ rims. And a matching headset. Sweet!